When comparing the efficiency of different wind turbine blade designs, [AdamEnt] found using a hair dryer wasn’t the best tool for the job. Enter his new 3D-printed wind tunnel.

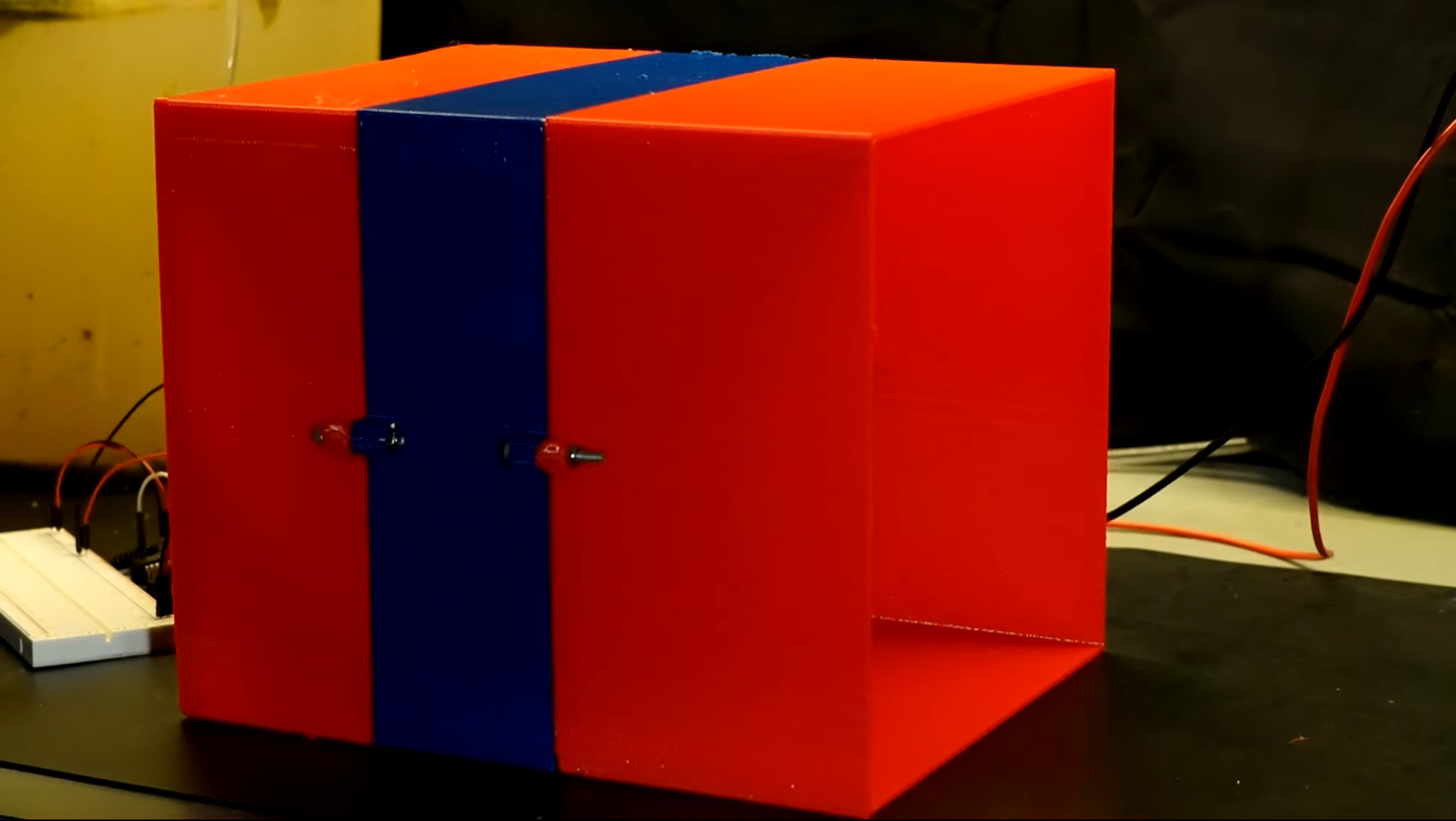

After several prototypes, [AdamEnt] decided on a design that exploits slicer infill to create a flow straightener without having to do any tedious modeling of a lattice. Combined with a box on both ends of the straightener to constrain the flow, he has a more controllable air source with laminar instead of turbulent flow for testing his wind turbines.

The BLDC motor driving the air is attached to a toroidal blade of MIT fame. We get a little bit of the math behind calculating wind turbine efficiency and see a quick test of a blade placed next to the outlet of the air source at the end of the video.

If you’re planning on building your own wind tunnel, we’ve covered a few. We’ve even seen one that goes up to Mach 20, although that probably wouldn’t be useful for wind turbine design!