Wiremold is great stuff — it’s relatively cheap, easy to work with, and offers all sorts of adapters and angle pieces which take the hassle out of running (and hiding) wires. But [Dr. Gerg] found a shortcoming of this otherwise very flexible product: since each run is intended to start and end in a surface mounted box, he couldn’t find an end cap that would let him close off a section.

The solution? A desktop 3D printer and a chunk of OpenSCAD code telling it what to extrude. When you break it down, the Wiremold profile is fairly straightforward, and can be easily described with geometric primitives. A handful of cylinders, a cube or two, tie it all together with the

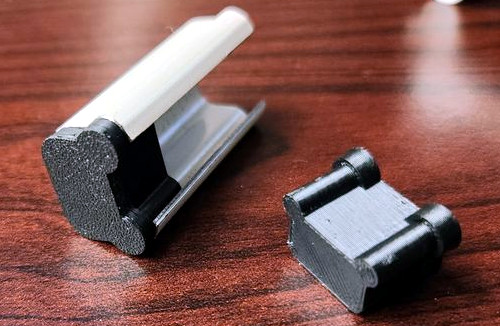

The solution? A desktop 3D printer and a chunk of OpenSCAD code telling it what to extrude. When you break it down, the Wiremold profile is fairly straightforward, and can be easily described with geometric primitives. A handful of cylinders, a cube or two, tie it all together with the hull() function, and you’re there.

We’d say this would be a fantastic project to cut your OpenSCAD teeth on, but since [Dr. Gerg] was kind enough to share the source code, you don’t have to figure it out on your own. Though there’s still benefit in reading over it if you’re looking for some practical examples of how the “Programmers Solid 3D CAD Modeller” gets things done.

So why would you want a Wiremold endcap? In the case of [Dr. Gerg], it sounds like he was trying to cover up a short run of wire that was running vertically. But we could imagine other applications for this basic design now that it’s out in the wild. For example, a short length of Wiremold outfitted with a pair of printed caps could make for a nice little enclosure if you’ve got a small project that needs protecting.