[ad_1]

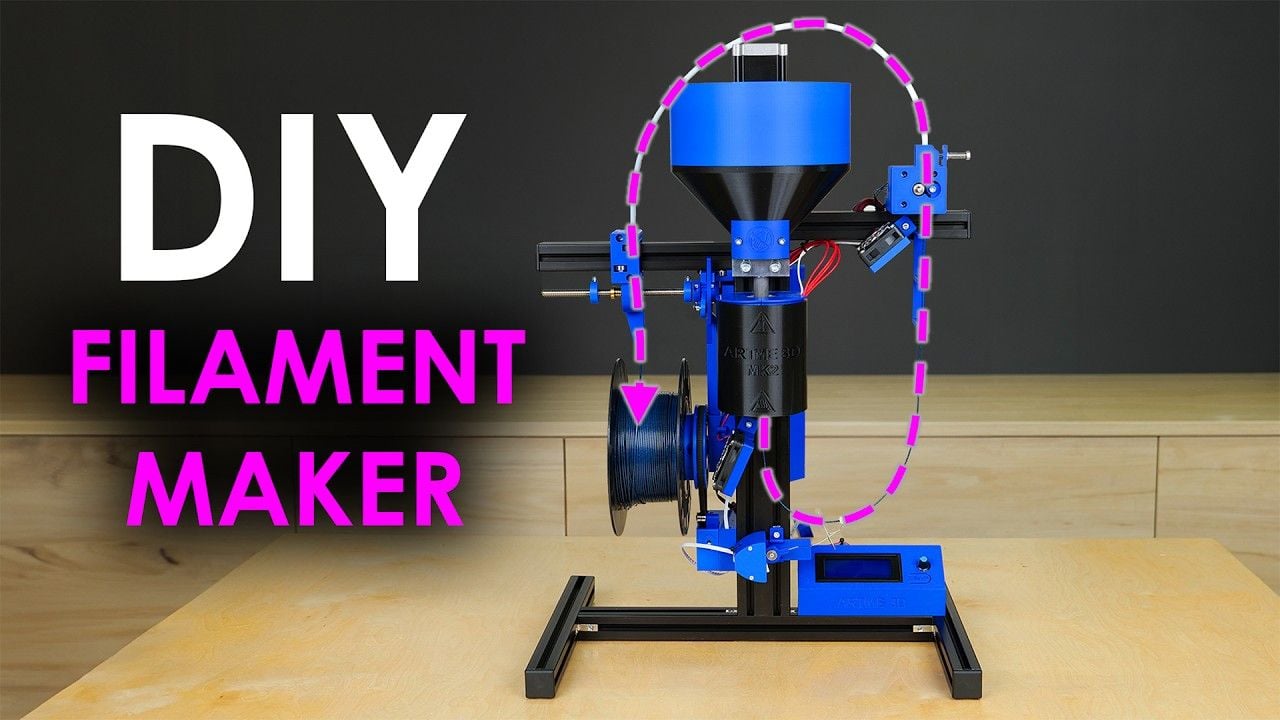

The world of 3D printing is constantly evolving, and with the increasing focus on sustainability, innovative solutions like the Artme3D MK2 3D print recycler and filament maker are taking center stage. This DIY filament extruder is designed to enable users to transform 3D printing waste into new, usable 3D printing filament, by creating a sustainable cycle of reuse and minimizing environmental impact. Simply break your old 3D prints and at them to the hopper at the top to start creating new recycled 3D printing filament. Depending on your experience in building such kits, you should allow between 7 and 16 hours for assembly say it’s designers.

3D Printing Filament Maker

The Artme3D MK2 comes as a self-assembly kit, accompanied by a comprehensive, multi-language manual that guides users through the assembly process step by step. At its core, the MK2 is designed to efficiently convert dried, shredded 3D print waste into fresh filament, ready for immediate reuse in new projects. The kit’s user-friendly features include:

- Detailed assembly instructions suitable for users of various skill levels

- Compatibility with a wide range of 3D printing waste materials

- Compact design that fits seamlessly into most workshop spaces

One of the key highlights of the Artme3D MK2 is its custom-designed feeding screw, specifically tailored for optimal material handling. This crucial component ensures consistent feeding of shredded waste into the extruder, streamlining the recycling process and minimizing potential jams or inconsistencies.

In addition, the MK2 features a built-in melt filter, which plays a vital role in purifying the recycled filament by eliminating impurities and ensuring the quality of the final output. This advanced filtration system helps maintain the integrity of the recycled filament, allowing users to create high-quality 3D prints using materials that would otherwise be discarded.

Energy Efficiency and Maintenance

Despite its advanced functionality, the Artme3D MK2 is designed with energy efficiency in mind. The extruder features low power consumption during operation, making it an eco-friendly choice for environmentally conscious users. Additionally, maintenance of the MK2 is relatively simple, primarily involving routine cleaning of the melt filter to prevent clogs and ensure optimal performance.

Here are some other articles you may find of interest on the subject of 3D Printing

The MK2’s energy efficiency and easy maintenance not only support environmental sustainability but also contribute to cost-effectiveness in terms of operational expenses. By minimizing energy consumption and reducing the need for frequent repairs or replacements, the Artme3D MK2 offers a cost-effective solution for users looking to adopt sustainable 3D printing practices.

Customization and Open Source Design

One of the most appealing aspects of the Artme3D MK2 filament maker is its partially open-source design, which invites users to customize and enhance the setup according to their specific needs and preferences. This feature is particularly attractive to tech enthusiasts, hobbyists, and researchers who value the ability to modify and optimize their equipment to suit their unique requirements.

The open-source nature of the MK2 encourages collaboration and innovation within the 3D printing community. Users can share their modifications, improvements, and experiences with others, fostering a sense of community and driving the development of new, sustainable 3D printing solutions.

Assembly and Practical Considerations

While the Artme3D MK2 filament maker comes as a self-assembly kit, it is important to note that some plastic parts required for the assembly are not included and must be 3D printed separately. The detailed setup process involves assembling the extruder, filament winder, and ensuring proper insulation using materials such as rock wool.

Although the assembly process may require some technical skills and patience, the comprehensive manual and supportive online community make it accessible to users with varying levels of experience. The satisfaction of building your own filament extruder and contributing to sustainable 3D printing practices makes the assembly process a rewarding experience.

Performance and Output Quality

While the filament produced by the Artme3D MK2 may not consistently match the uniform precision of commercially available filament, it is more than adequate for a wide range of 3D printing applications. The MK2 is an excellent choice for hobbyists, educators, and environmentally conscious individuals who are interested in exploring the use of recycled materials in their 3D printing projects. The Artme3D MK2 offers a balance between sustainability, cost-effectiveness, and performance. By allowing users to create their own filament from recycled materials, the MK2 reduces the reliance on virgin materials and contributes to a more circular economy in the 3D printing industry.

The Artme3D MK2 is a innovative tool that empowers users to adopt sustainable 3D printing practices, reduce waste, and create a closed-loop system for filament production. Despite the initial challenges of assembly and the potential for minor inconsistencies in filament quality, the long-term benefits of the MK2 far outweigh these considerations. By using the Artme3D MK2, users can not only reduce their environmental impact but also enjoy the satisfaction of creating their own filament and contributing to a more sustainable future in 3D printing. As the world continues to prioritize eco-friendly solutions, the Artme3D MK2 stands out as a pioneering tool that paves the way for a greener, more innovative approach to additive manufacturing.

Video Credit: Source

Filed Under: DIY Projects

Latest Geeky Gadgets Deals

Disclosure: Some of our articles include affiliate links. If you buy something through one of these links, Geeky Gadgets may earn an affiliate commission. Learn about our Disclosure Policy.

[ad_2]

Ahmed Ibrahim

Nice one