It’s problem which faces many a piece of older equipment, that ribbon cables of the type used on membrane keyboards start to fail as they become older. These cables are extremely difficult to repair as they can’t be soldered to, and since they are usually custom to the device in question. All is not lost though, as [Spare Time Repair] shows us with the cable on a Honeywell heating controller broken by a user attempting to remove the battery with a screwdriver.

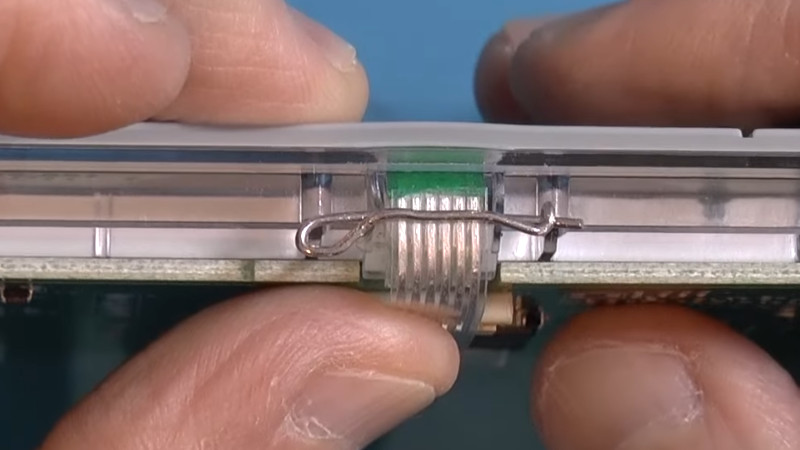

The whole process can be seen in the video below the break, and it involves the use of a vinyl cutter to cut the pattern of tracks in aluminium tape stuck on a sheet of acetate. This makes a new piece of ribbon cable, however it’s still a step short of being part of the circuit. His challenge is to make a clip tight enough to attach it to the intact part of the broken cable and maintain contact, then to hope that the new piece of cable bent back on itself can make enough contact for the device to work.

At the end of it all he has a working Honeywell controller, though as he points out it’s a device he has little interest in. Instead this opens a window on an extremely useful technique that should be of relevance far beyond the world of heating. There’s one machine close to home for us that could use this technique, for example.

Asabilly

Nice

Victor osuhon

Good