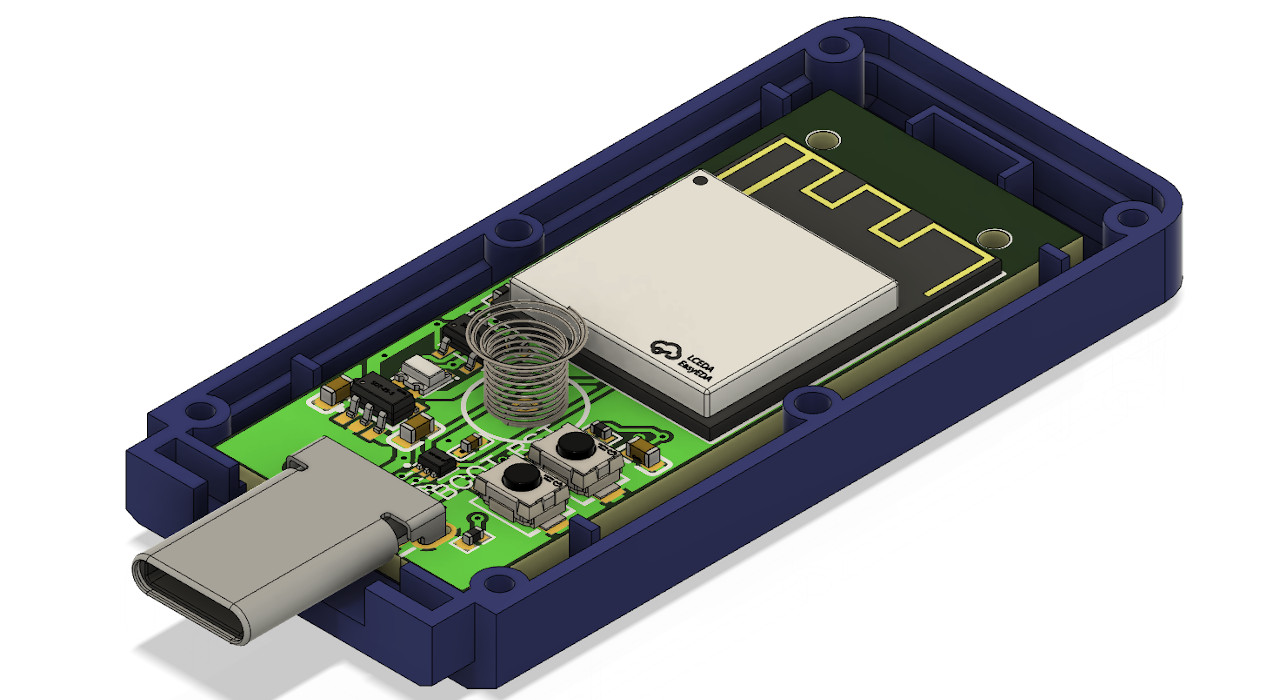

When [Daniel Eichhorn] designed the Pendrive S3 project, he wanted to use an off-the-shelf USB enclosure but also add a button for the user to start certain actions. Drilling a hole into the enclosure would be an option, but decided a touch sensor on the top of the enclosure would be much more elegant — not to mention better at keeping dirt and moisture out. To bridge the 6.3 mm spacing between the PCB and the top of the enclosure [Daniel] used a small, 7 mm PCB-mounted spring.

Although capacitive sensing works with just about anything that’s electrically conductive, it’s important to get the conductive element as close to the user’s digits as possible. Using a spring here has the advantage that when the enclosure is closed up, the lid will push down onto the spring, which will not only compress slightly, but also provide the best capacitive sensing experience when e.g. the enclosure flexes or warps over time on account of always being pressed against the inside of the lid.

While hardly world-changing, this is another neat design tip when you’re looking to turn more surfaces into touch controls. Just keep in mind that capacitive sensing is notoriously fussy and any trace and spring are also excellent antennae for stray EMI. Nobody likes random capacitive button inputs, after all.