Climbers care a lot about their ropes because their lives literally depend on them. And while there’s been tremendous progress in climbing rope tech since people first started falling onto hemp fibers, there are still accidents where rope failure is to blame.

This long, detailed, and interesting video from [Hard is Easy] follows him on a trip to the Mammut test labs to see what’s up with their relatively new abrasion-resistant rope. His visit was full of cool engineering test rigs that pushed the ropes to breaking in numerous ways. If you climb, though, be warned that some of the scenes are gut-wrenchingly fascinating, watching the ropes fail horribly in well-shot slow-mo.

Long story short, some climbing ropes are strong but stiff. These are called static ropes, and they’re rated to hold a given weight, and tested to breaking under a static load. The thinnest and strongest static ropes are made of Kevlar, and they are correspondingly very abrasion resistant, but they hurt to fall into.

Dynamic climbing ropes have some stretch, and are rated both for how gently they let you down and their maximum breaking force. These are mostly made of nylon, and they are tested by dropping a mass with an accelerometer onto a slack rope — a pretty good simulation of falling back off of a flat face like at the climbing gym.

Dynamic climbing ropes have some stretch, and are rated both for how gently they let you down and their maximum breaking force. These are mostly made of nylon, and they are tested by dropping a mass with an accelerometer onto a slack rope — a pretty good simulation of falling back off of a flat face like at the climbing gym.

Now what if you wanted an abrasion resistant dynamic rope? A couple of manufacturers have created custom Kevlar-nylon filaments where the Kevlar is wrapped loosely around the nylon. This filament is abrasion resistant because of the Kevlar, but gives like a nylon rope because the Kevlar fibers have slack built in.

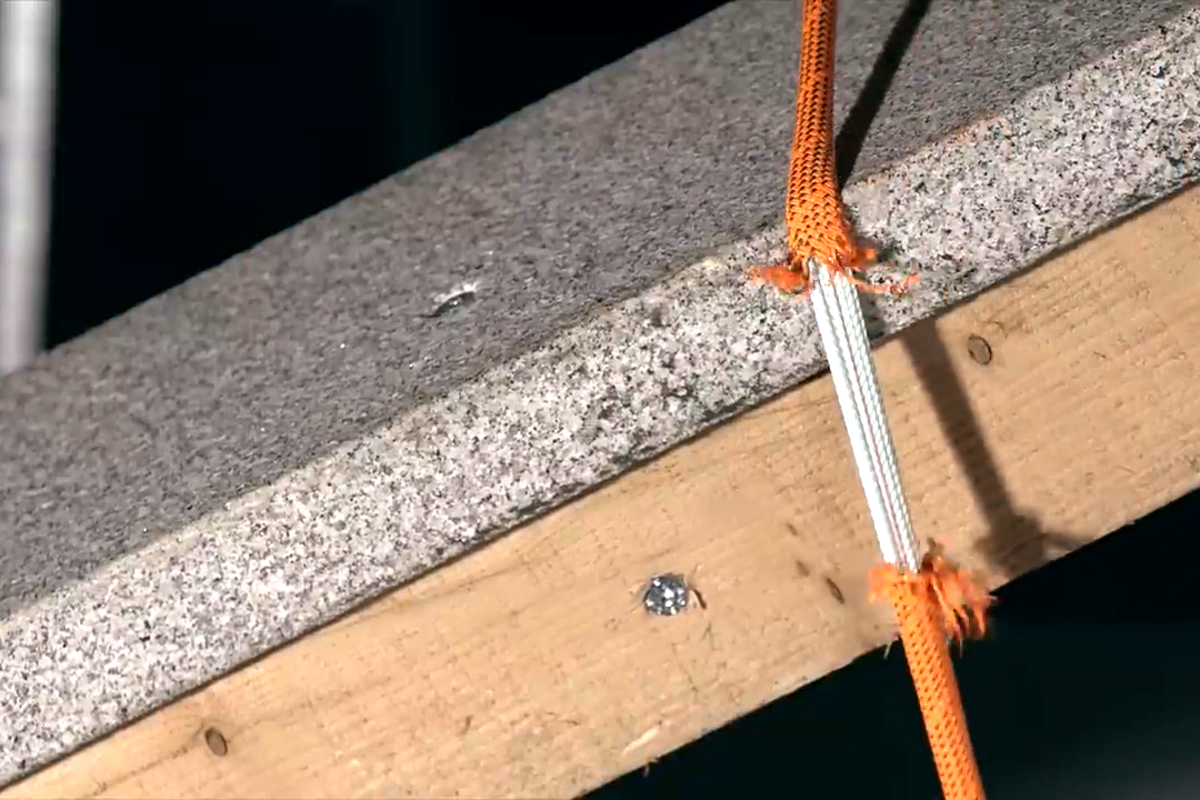

Testing these ropes involved creating a custom test that drops a mass onto the rope, but pulls it across a 45-degree granite edge as it falls. These tests absolutely shred the normal nylon dynamic ropes, but the Kevlar-reinforced ropes held fast. They’re both fun and terrifying to watch.

We’ve said it before, and it’s said a number of times in this video: “you can’t improve what you can’t measure“. In this context, it’s a little sobering is that there isn’t an industry standard test for abrasion resistance, but it’s cool to see the Mammut folks working on it.